The Resilience and Innovation of the Mould Industry

The mould industry is a pivotal sector that underpins numerous other industries, enabling the efficient production of a wide range of products. Within this realm, plastic mold makers and plastic injection mould manufacturers play a significant role, contributing to innovations and advancements that shape today's manufacturing landscape. In this comprehensive article, we will delve deeply into the intricacies of the mould industry, exploring its challenges, advancements, and the crucial elements that ensure its continuous evolution.

An Overview of the Mould Industry

The mould industry primarily revolves around the design, production, and maintenance of moulds used in manufacturing processes. Such moulds are essential in creating parts and products across various industries, including automotive, consumer goods, electronics, and medical devices. The mould industry is driven by the demands for precision, efficiency, and adaptability; it is crucial for meeting the ever-evolving needs of the market.

Key Components of the Mould Industry

- Design and Engineering: This phase involves the development of intricate designs that meet specific product requirements. Computer-Aided Design (CAD) software plays a vital role in crafting accurate mould designs.

- Material Selection: Choosing the right materials for mould construction is crucial, as it affects durability, cost, and the quality of the finished product.

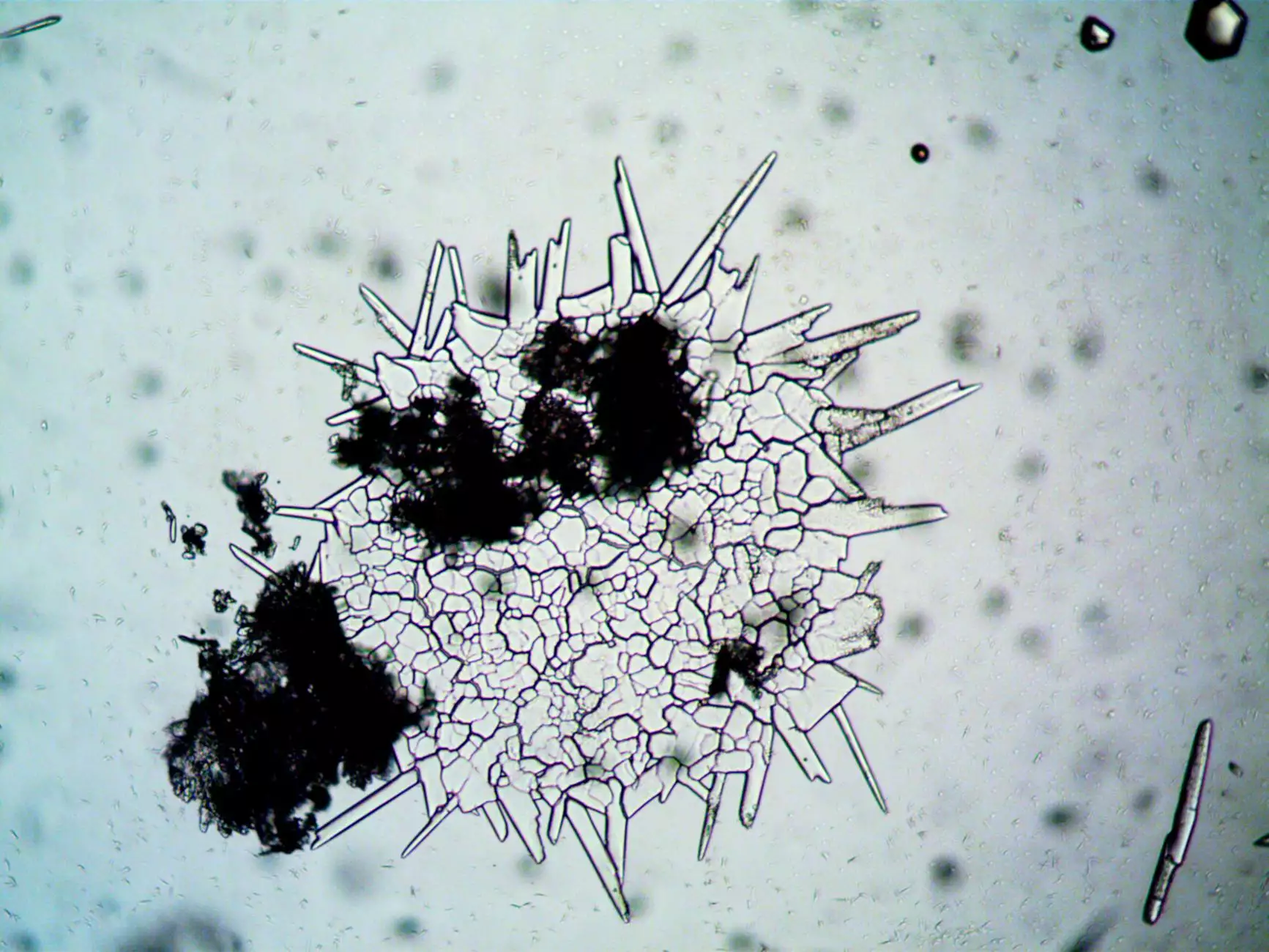

- Manufacturing Processes: The mould manufacturing process includes techniques such as CNC machining, wire EDM, and injection moulding itself.

- Maintenance and Repair: Regular maintenance of moulds ensures longevity and usability, minimizing downtime and production losses.

The Importance of Plastic Mould Makers

Plastic mould makers are the backbone of the mould industry. Their expertise and craftsmanship are required to produce high-quality moulds capable of yielding thousands of identical parts. The ability to create durable and precise moulds directly influences product quality, production speed, and overall operational efficiency.

Innovations in Plastic Mold Making

The mould industry has witnessed significant innovation in recent years. Some noteworthy advancements include:

- 3D Printing Technology: This technology allows for rapid prototyping and the creation of complex geometries that were once thought impossible. It reduces lead times and enhances design flexibility.

- Smart Manufacturing: The integration of IoT (Internet of Things) technology in manufacturing processes enables real-time monitoring and data collection, contributing to improved production efficiency.

- Sustainable Practices: As environmental concerns rise, many plastic mould makers are adopting sustainable practices, including the use of eco-friendly materials and reducing waste through efficient manufacturing processes.

Plastic Injection Mould Manufacturers: The Heart of Mass Production

Plastic injection mould manufacturers are crucial in the mass production of plastic components. This technique involves injecting molten plastic into a mould cavity, where it cools and solidifies to form the desired shape. This process is not only efficient but also allows for a high degree of manufacturing precision.

A Look at Injection Moulding Processes

The injection moulding process can be broken down into several stages:

- Material Preparation: The first step involves drying and mixing the plastic materials before they are melted.

- Injection: The melted plastic is injected into the mould at high pressure.

- Cooling: The molten plastic cools and solidifies within the mould.

- Mould Opening: After sufficient cooling, the mould opens, and the finished product is ejected.

The entire process can be automated, which further enhances efficiency and reduces labor costs. Additionally, manufacturers can produce large quantities of intricate parts in a relatively short amount of time, making injection moulding one of the most popular manufacturing methods in the mould industry.

Challenges Facing the Mould Industry

- Global Competition: As production facilities and expertise become more globally accessible, manufacturers face increased competition from overseas.

- Rising Material Costs: Fluctuations in raw material costs can affect profit margins and overall production costs.

- Technological Advancements: Keeping up with rapid technological advancements and evolving customer demands requires continuous investment in research and development.

Future Trends in the Mould Industry

Looking ahead, several trends are expected to shape the future of the mould industry:

- A Shift Toward Automation: The adoption of robotic automation in the manufacturing process will enhance precision, reduce the likelihood of errors, and increase production speeds.

- Integration of AI: Artificial Intelligence (AI) will play a crucial role in optimizing the supply chains, predicting maintenance needs, and improving the overall productivity of mould production.

- Customization and Complexity: As consumer preferences shift towards personalized products, the demand for custom moulds and complex geometries will continue to rise.

- Sustainability Initiatives: The shift toward sustainable practices will accelerate, with more companies focusing on reducing their carbon footprint and improving recycling capabilities.

Conclusion: The Vital Role of the Mould Industry

The mould industry is an indispensable pillar of modern manufacturing, with plastic mould makers and injection mould manufacturers at the forefront of production innovation. As industries demand higher quality, faster production, and sustainable practices, the mould industry will continue to adapt, innovate, and thrive. Keeping abreast of the latest trends, technologies, and practices will be essential for companies looking to maintain a competitive edge in this dynamic landscape.

For companies like Hanking Mould, which specialize in plastic mould making and plastic injection mould manufacturing, understanding these dynamics is paramount. By investing in quality craftsmanship, embracing innovation, and committing to sustainable practices, businesses in the mould industry can not only meet the current market demands but also pave the way for future advancements.