Understanding the Importance of Slitting Circle Blade in Modern Manufacturing

The manufacturing industry has witnessed a tremendous evolution over the decades, with precision and efficiency becoming vital elements of production processes. Among the myriad of tools that have become essential, the slitting circle blade plays a pivotal role. This article aims to delve into every aspect of slitting circle blades, including their design, materials, applications, and maintenance.

What is a Slitting Circle Blade?

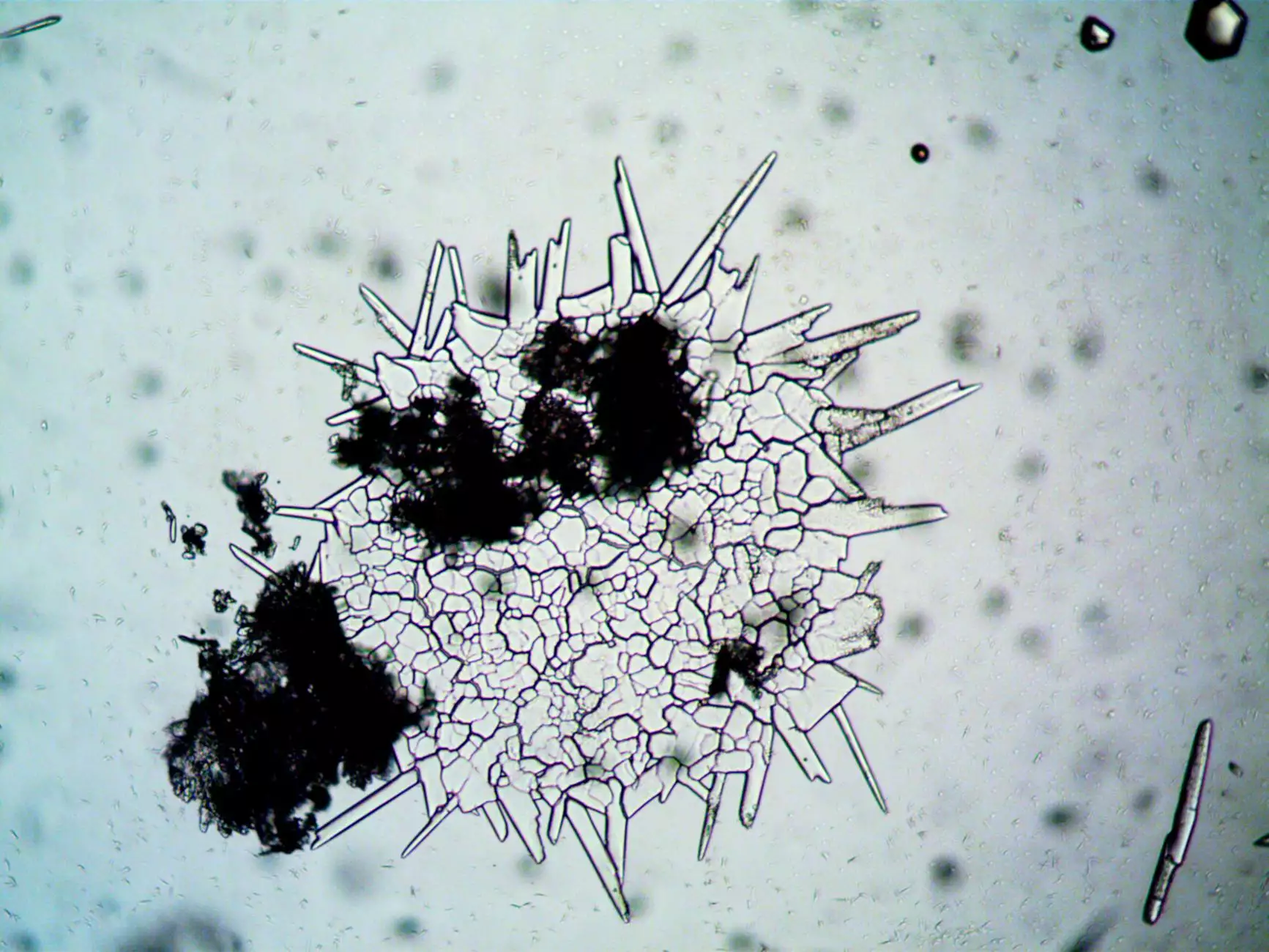

A slitting circle blade is a circular cutting tool used for slicing materials into precise dimensions. Typically used in slitters, these blades are designed to cut various materials such as paper, film, and metal. The circular design allows for smooth, continuous cutting, making it ideal for high-speed production environments.

Key Features of Slitting Circle Blades

When it comes to slitting circle blades, certain features set them apart. Below are some key characteristics:

- Circular Shape: This design allows for easy rotation during the cutting process, minimizing friction and wear.

- Material Composition: Typically made from high-speed steel (HSS), carbide, or specialized steel, these materials enhance durability and edge retention.

- Precision Engineering: High manufacturing standards ensure that these blades are finely tuned for accuracy.

- Varied Thickness: Available in various thicknesses, they can be customized based on the specific cutting requirements.

Types of Slitting Circle Blades

Slitting circle blades come in different types, each suited for particular applications. Understanding these types can help manufacturers select the most effective one for their needs. Here are the most common types:

- Standard Slitting Blades: Ideal for general purposes; these blades are commonly used in various industries.

- High-Speed Steel Blades: Offer excellent wear resistance and cutting speed, suitable for high-volume applications.

- Carbide-Tipped Blades: Known for their robustness, these blades can effectively handle harder materials.

- Custom Blades: Tailored to meet specific cutting needs of different applications, often made based on unique material requirements.

Applications of Slitting Circle Blades

The versatility of slitting circle blades allows them to be utilized across various sectors. Some prominent applications include:

- Paper and Packaging: Used for cutting paper rolls and packaging materials into desired sizes and shapes.

- Textiles: Essential in the textile industry for cutting fabrics, ensuring precision in garment production.

- Metalworking: Employed in the metal industry to slice sheets and rods into specified dimensions.

- Composites: Efficient for cutting composite materials in manufacturing applications, particularly in aerospace and automotive industries.

Factors to Consider When Choosing a Slitting Circle Blade

Selecting the right slitting circle blade is crucial for achieving optimal performance. Here are some factors manufacturers should consider:

Material Compatibility

Understanding the material being cut is vital. Each material has different hardness and density, which influences the blade type required. It's important to choose a blade that can withstand the specific attributes of the material for clean and efficient cuts.

Blade Thickness

Thickness affects the cutting performance. A thicker blade can handle tougher materials but may generate more heat. Conversely, a thinner blade may provide finer cuts but might be less durable.

Cutting Speed

Different blades are rated for different cutting speeds. Manufacturers must ensure that their selected blade matches the speed of their machinery to maintain efficiency and minimize wear.

Blade Coating

Some blades come with specialized coatings that enhance performance, reduce friction, and extend lifespan. Consideration should be given to the environmental conditions in which the blade will be used.

Maintenance of Slitting Circle Blades

Proper maintenance of slitting circle blades is essential to extend their lifespan and maintain cutting efficiency. Here are several tips for effective maintenance:

- Regular Inspection: Routine checks can help identify wear or damage early, preventing further issues.

- Sharpening: Blades should be sharpened regularly according to the manufacturer’s recommendations to ensure optimal cutting performance.

- Cleaning: After use, blades should be thoroughly cleaned to remove any material buildup that could affect their performance.

- Proper Storage: Store blades in protective cases to avoid damage when not in use.

The Future of Slitting Circle Blades

As technology advances, the future of slitting circle blades looks promising. Innovations such as laser-cutting and computer numeric control (CNC) machining are enhancing the precision and efficiency of production processes. Manufacturers like SZBlade are at the forefront of this innovation, offering state-of-the-art slitting circle blades that cater to modern industrial needs. The continuous evolution in materials and blade design will likely result in improved performance, reduced costs, and greater sustainability.

Conclusion

In conclusion, the slitting circle blade is an indispensable tool in modern manufacturing. Its significance transcends various industries, promoting efficiency, precision, and sustainability. Understanding the features, types, applications, and maintenance of slitting circle blades empowers manufacturers to make informed decisions. Investing in quality blades, such as those offered by SZBlade, can lead to improved productivity and cost-effectiveness, setting businesses on the path to success.